Lasers for grating manufacturing

Create high quality optical gratings with DPSS lasers designed for precision, high throughput fabrication

The fabrication and manufacture of high quality optical gratings depends on the stability, coherence, and wavelength of the laser source used in mastering. Our 320 nm continuous wave DPSS single frequency laser provides a solid-state alternative to helium cadmium (HeCd) laser systems, offering long coherence length, narrow linewidth, uniform intensity, and stable operation for reliable grating production.

Compared with a typical HeCd source, the Skylark NX 320 nm DPSS laser delivers higher usable output power, more than four times that of a standard HeCd laser, while maintaining stable operation over extended periods. The Skylark NX laser architecture provides superior spatial coherence and a TEM₀₀ Gaussian beam profile, ensuring uniform interference fringes during grating mastering. This combination of higher, reliably available UV power and excellent beam quality enables faster exposure times and more consistent grating structures than are achievable with conventional HeCd lasers.

320 nm

up to 200 mW

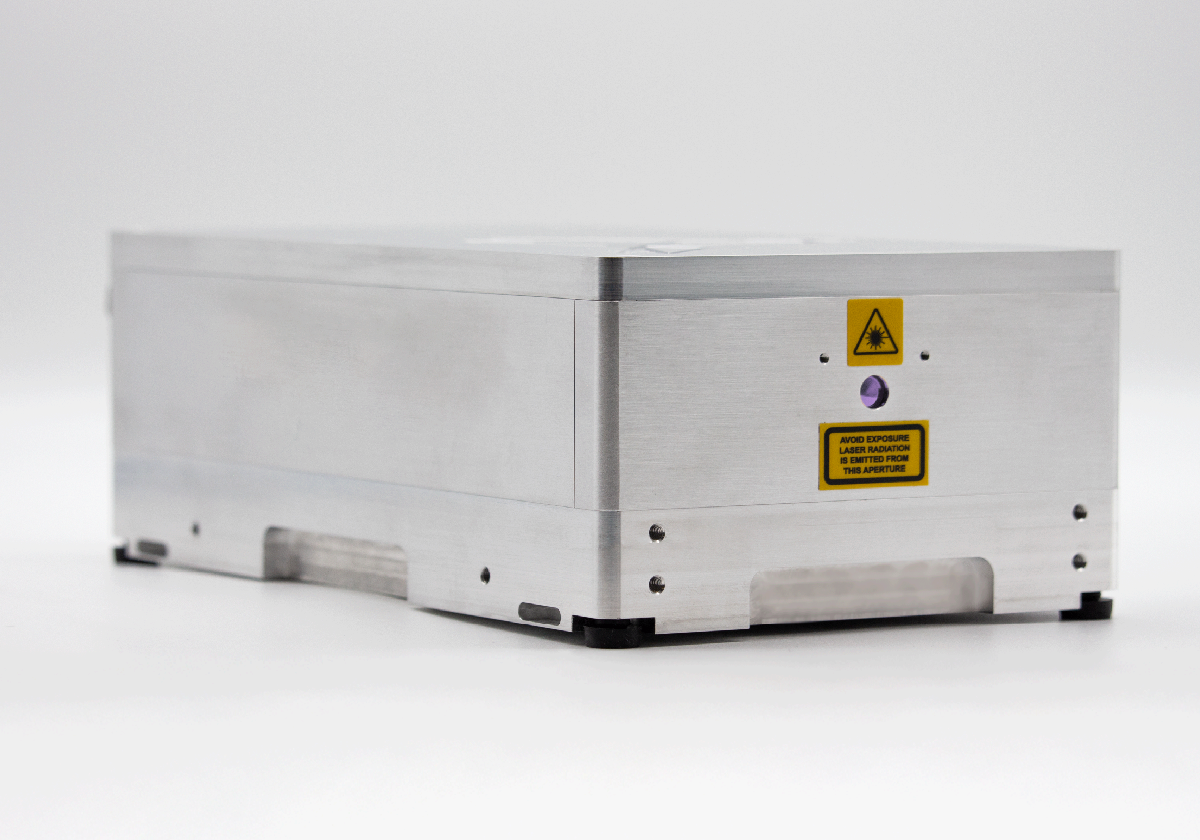

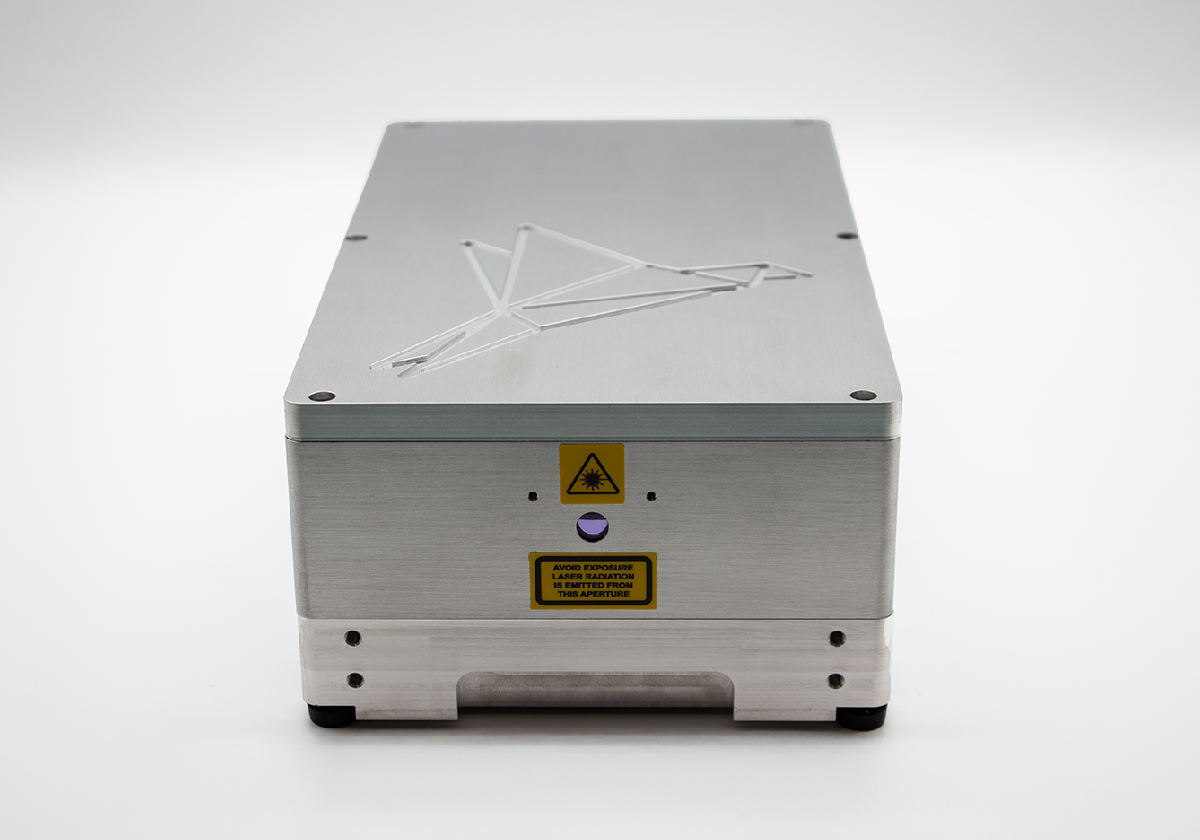

Skylark 320 NX

320 nm single frequency DPSS UV laser

349 nm

up to 400 mW

Skylark 349 NX

349 nm single frequency DPSS UV laser

Uniform intensity

≤ 0.3% RMS

Stable power

≤ 2.0%

Power stability ensures consistent exposure during fabrication, enabling repeatable grating efficiency and uniform modulation across substrates.

Uniform beam

M² ≤ 1.2

Consistent wavelength

± 0.2 pm

Stable wavelength over extended periods, ensuring spectral consistency and uniform grating formation.

Single frequency DPSS lasers produce high resolution, high fidelity optical gratings

Skylark NX lasers power applications in several optical grating mastering processes due to their uniform intensity, ultra-stable output, and coherence. Using the Skylark 320 NX or 349 NX, create high quality, high fidelity optical gratings using various mastering techniques and applications:

Volume Bragg gratings (VBGs), Chirped Volume Bragg gratings (CVBGs), grating-based sensors, diffractive optical elements (DOEs), diffraction grating fabrication, laser interference lithography, holography, spectroscopy, interferometry, lithography.

Chirped Volume Bragg gratings (CVBGs)

Chirped volume Bragg gratings have a varying periodicity along the grating length. The long coherence length and stable UV output of our single frequency 320 nm laser support precise recording of chirped profiles with high uniformity.

Linear gratings

Linear gratings consist of parallel lines or grooves etched at uniform intervals. Their performance depends on the groove spacing and depth.

Blazed gratings (symmetric, sinusoidal)

Blazed gratings have grooves shaped into a specific angle, optimized for directing light into a preferred diffraction order. Symmetric blazed gratings have evenly spaced, sharp grooves, while sinusoidal gratings have a wave-like structure.

Crossed gratings

Crossed or checkerboard gratings are formed by two sets of linear gratings etched perpendicularly to each other, creating a 2D grid that manipulates light in two dimensions.

Diffractive optical elements (DOEs)

Diffractive optical elements use microstructured patterns to control and shape light. DOEs can split, focus, or homogenise beams with high efficiency for applications in beam shaping, laser material processing, and advanced imaging. Precision mastering with a stable 320 nm single frequency laser ensures uniform feature size and high diffraction efficiency.

Transmission and reflection holographic gratings

Transmission gratings diffract light as it passes through the grating substrate, while reflection gratings redirect light off the surface. Both are widely applied in spectroscopy, metrology, and beam analysis. Single frequency 320 nm DPSS lasers provide the spatial coherence and beam uniformity required for producing transmission and reflection gratings with sharp, reproducible features.

Laser interference lithography (LIL)

Laser interference lithography (LIL) is used to create periodic structures for optical gratings by overlapping coherent UV beams on a photosensitive material. At 320 nm, a single frequency CW DPSS laser provides sufficient coherence and stability to form uniform interference fringes, enabling accurate and repeatable grating fabrication. This approach supports the production of surface relief gratings, photonic lattices, and volume Bragg gratings for applications in optics and photonics.

"It's taken 15 years to find a suitable replacement for our HeCd lasers. The Skylark 320 NX offers a suitable, stable alternative with the uniform intensity we need for fabricating gratings."

FAQS

Switching from HeCd to DPSS lasers

REQUEST A QUOTE